Embodied Carbon

What is embodied carbon?

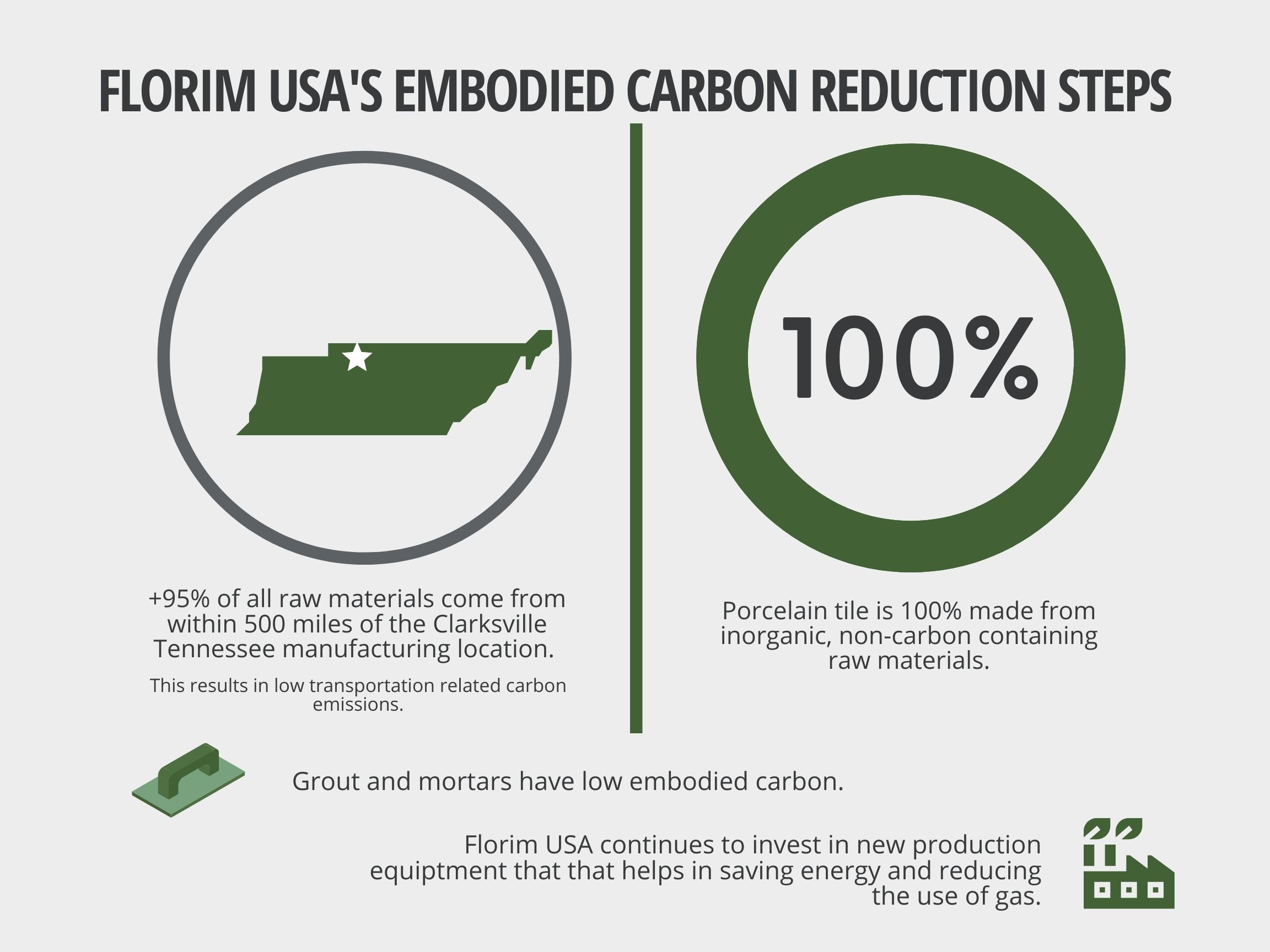

Embodied carbon is the sum of all the greenhouse gas emissions (mostly carbon dioxide) resulting from the mining, harvesting, processing, manufacturing, transportation and installation of building materials. The global warming emissions associated with these materials, along with emissions associated with construction itself, are the “embodied carbon footprint” of design and construction. Smart choices during design can greatly reduce this footprint. Florim USA takes several steps to reduce the embodied carbon of our product. Some of these steps are:

- +95% of all raw materials come from within 500 miles of the Clarksville Tennessee manufacturing location. This results in low transportation related carbon emissions.

- Grout and mortars have low embodied carbon.

- Porcelain tile is 100% made from inorganic, non-carbon containing raw materials.

What are the impacts of embodied carbon?

Embodied carbon emissions from a building are released during the manufacturing processes of components that contribute to the building and begins with sourcing raw materials and ends with the completion of construction also from operating carbon emissions – from heating, cooling, lighting, and maintenance loads — that occur over the life of a building, which can be 50 years or more. When looking at total greenhouse gas emissions for new buildings built over the next ten years — the critical period for action to address the global climate emergency — it is estimated that 80% will come from embodied emissions, so lowering embodied carbon emissions is now even more urgent than lowering operating emissions which comprise the remaining 20%.

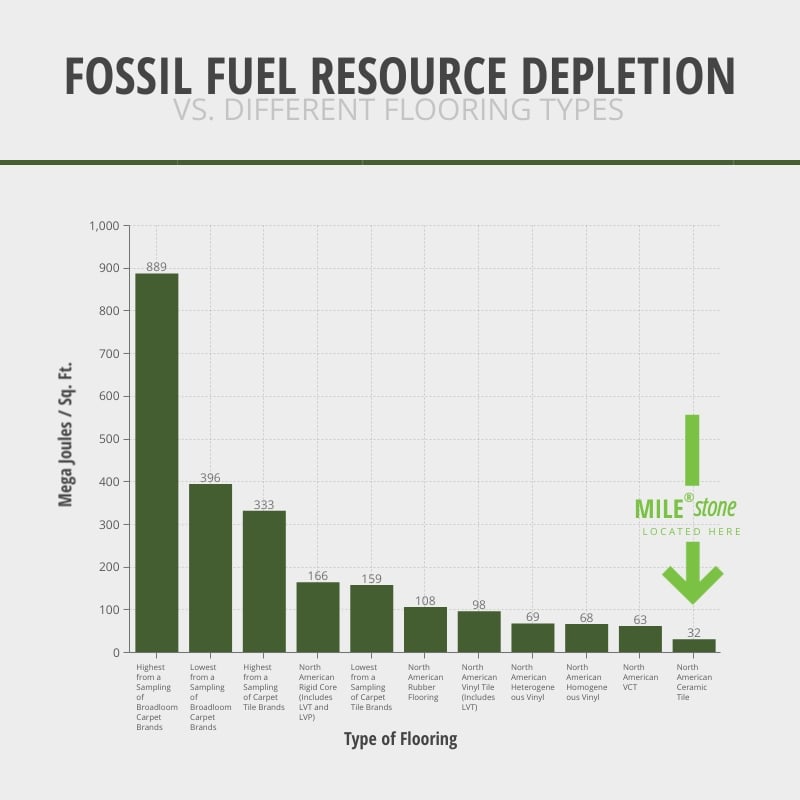

Porcelain tile contains the least embodied carbon of any competitive floor covering. This is partly due to its long useful life thus avoiding replacement. Thoughtful selection of timeless porcelain tile designs results in a floor or wall covering that can easily last the life of the building resulting in reduced carbon emissions from manufacturing, construction, demolition, and waste management.

What about existing buildings and materials?

Renovating, remodeling, and repurposing existing buildings almost always generates significantly fewer embodied emissions than new construction. Finding creative ways to reuse existing buildings is an increasingly important strategy for reducing embodied emissions. The urgent need to reduce greenhouse gas emissions in the short term means that the calculus for saving rather than demolishing an existing building has changed and is now weighed much more heavily against demolition. Reusing buildings also offers the opportunity to reduce current operating emissions from existing building through deep energy upgrades, so they can contribute in the long term as well as the short term.

Porcelain tile is readily used in renovation projects. Leveling mortars, which may be necessary in a remodel, have very low embodied carbon resulting in a complete installation with significantly less embodied carbon than carpet or LVT.

How do you calculate carbon?

There are a number of tools available for calculating embodied carbon. Some of these tools are meant for quick, early estimates while others take a deeper dive. More information on these tools can be found in the resources section at the end of this document. There are also data bases that evaluate the life cycles of products and a growing number of environmental product declarations (EPDs) for specific products or product categories that document product global warming potential.

Florim has prepared an EPD for all tile manufactured at the Clarksville factory to support analyses of low embodied carbon in tile installations. There is also an industry wide EPD for the porcelain tile industry in the US to support broader comparisons of flooring types.

How MILE®stone Porcelain Tile Reduces A Building’s Embodied Carbon

According to third party review, porcelain tile has a useful life of at least 75 years. This longevity ensures reduced repair, demolition and disposal requirements resulting in reduced energy demand and transportation needs with corresponding reductions in carbon emissions.

According to third party review, porcelain tile has a useful life of at least 75 years. Thoughtful selection of timeless porcelain tile designs results in a floor or wall covering that can easily last the life of the building, without requiring replacement, resulting in reduced carbon emissions from manufacturing, construction, demolition, and waste management.

Porcelain tile is readily used in renovation projects. Leveling mortars have very low embodied carbon resulting in a complete installation with significantly less embodied carbon than carpet or LVT.

Both industry-wide and Florim specific EPDs are available to support verification of low embodied carbon in tile installations.

MILE®stone tile has an exceptionally high recycled content, which provides an embodied carbon reduction due to reduced extraction, transportation, and processing requirements.

This reuse of materials avoids the mining of virgin raw materials and in some cases avoids or minimizes transportation requirements. Both actions reduce embodied carbon by avoiding the expenditure of energy.

The wide range of available porcelain tile sizes aids in producing a design with low material waste.

The Florim factory in Clarksville, Tennessee is within 500 miles of 1/3 of the US population. This easy access to such a large population base reduces transportation and its associated carbon emissions.

Over 95% of the raw materials used in the production of MILE®stone tile are sourced within a 500-mile radius of the Clarksville factory. This central location ensures transportation efficiency resulting in low carbon emissions from raw material transportation.

Porcelain tile has the lowest embodied carbon of any competing flooring product. Through our high recycled content and other recycling efforts, Florim is a major player in the circular economy.

Porcelain Tile in the Built Environment

How can Florim USA porcelain tile contribute to lower embodied carbon in the built environment?

A cultural dichotomy exists in the design of the built environment. People want both the “new shiny thing”, and they want permanence with its associated economies. The long life of porcelain tile in conjunction with wise tile selection can support both desires. Selection of a timeless tile design, such as Luxury Calacatta will allow for regular refreshing of other less long-lasting design elements in the space.

Porcelain tile is the lowest embodied carbon flooring option so such a long-term scheme would avoid the carbon loads of replacement flooring materials such as carpet or LVT.

How does porcelain tile reduce operational carbon in the built environment?

Under most conditions, porcelain tile requires only a little fresh water and a mop to maintain its beauty and safety. Power equipment and harsh cleaning chemicals are not required. Other flooring selections such as carpet require regular vacuuming and shampooing to maintain their appearance. Porcelain tile’s ease of maintenance avoids the use of both electricity and cleaning chemicals, reducing the operational carbon contribution of the flooring.